Maintaining Your Woodpecker i-Sensor: Best Practices and Recommendations

Share

Investing in high-quality digital imaging technology like the Woodpecker i-Sensor ensures precise diagnostics and improved patient care. However, to maximize its lifespan and maintain optimal performance, proper care and maintenance are essential. By following best practices, dental professionals can prevent damage, reduce repair costs, and ensure consistent image quality.

1. Proper Handling and Storage:

The i-Sensor is a delicate yet durable piece of equipment. To prevent accidental damage:

✔ Handle with care – Avoid dropping or bending the sensor.

✔ Use protective covers – Always place the sensor in a barrier sleeve before use.

✔ Store in a secure location – Keep it in a designated holder when not in use to avoid accidental falls.

✔ Avoid excessive force – When positioning the sensor in a patient’s mouth, ensure it is placed gently to prevent unnecessary strain.

2. Regular Cleaning and Disinfection:

Maintaining proper hygiene is crucial for both patient safety and the longevity of the device. Follow these steps for daily cleaning:

✔ Use recommended disinfectants – A non-alcoholic, non-abrasive disinfectant wipe is ideal for cleaning the sensor.

✔ Avoid soaking in liquids – The i-Sensor is not waterproof, so never submerge it in disinfectants or water.

✔ Gently wipe after each use – Immediately clean the sensor after each patient to prevent residue buildup.

✔ Sanitize the USB connector – Dust and debris can accumulate, affecting connectivity.

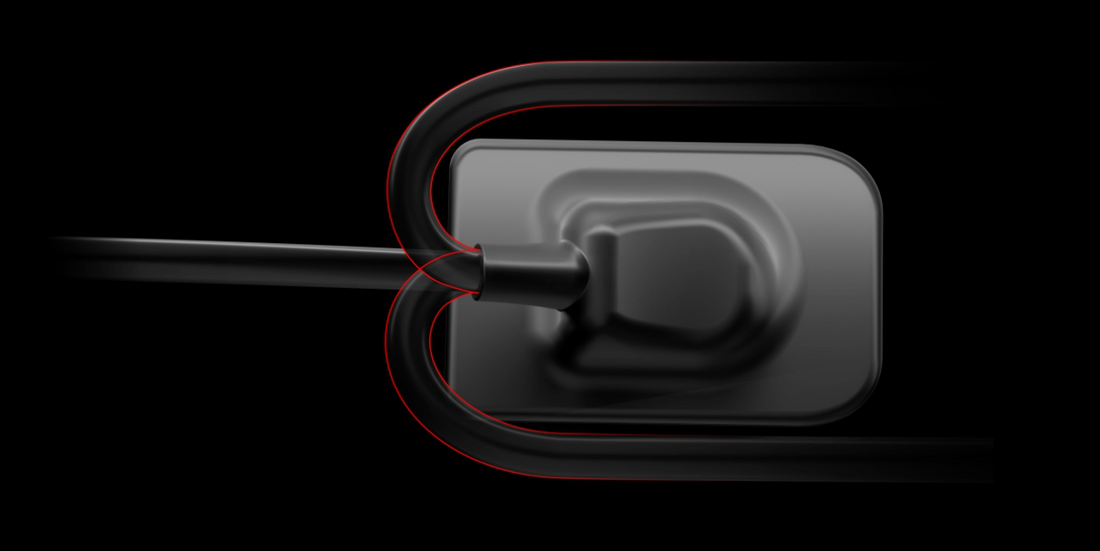

3. Managing Cables to Prevent Damage:

One of the most common issues with digital sensors is cable wear and tear. Protect the cable by:

✔ Avoiding excessive bending or twisting – Sharp bends can weaken internal wiring.

✔ Using a strain relief system – This prevents stress on the connection point.

✔ Not wrapping the cable too tightly – Loosely coil the cable when storing.

✔ Inspecting for damage regularly – Any exposed wires or frayed sections should be addressed immediately to prevent sensor failure.

4. Software Maintenance and Updates:

The performance of the i-Sensor is also dependent on its software compatibility and updates. Ensure:

✔ Regular software updates – Keep your imaging software up to date to maintain compatibility with newer systems.

✔ Routine system checks – Run diagnostics to detect any software or hardware issues.

✔ Proper data storage – Ensure patient images are backed up securely to avoid loss.

5. Troubleshooting Common Issues:

✔ If the sensor isn’t detected – Check USB connections and restart the imaging software.

✔ If images appear blurry – Ensure the sensor is positioned correctly and there is no moisture or debris on the lens.

✔ If connectivity issues arise – Try using a different USB port or restarting the computer.

For persistent problems, refer to the manufacturer’s guidelines or contact technical support.

6. Scheduling Professional Maintenance:

While routine care prevents most issues, periodic professional inspections can help detect potential problems before they escalate. Consider:

✔ Annual check-ups with your dental equipment provider.

✔ Replacing protective accessories (e.g., sensor holders) as needed.

✔ Reviewing staff handling procedures to reinforce best practices.

Conclusion: Protect Your Investment:

By properly maintaining the Woodpecker i-Sensor, dental professionals can ensure long-lasting performance, clear diagnostic imaging, and lower repair costs. Implementing these simple but effective practices will extend the sensor’s lifespan, making it a valuable long-term investment for any dental practice.

About the Author:

Dr. Rami Mousattat is the CEO of Dental Solutions and a former periodontist and trainer with extensive experience in the field of dental implants. With a career spanning several countries, Dr. Mousattat has trained numerous dentists in advanced techniques and continues to champion innovation and excellence in dental care.

Discover more about the I-Sensor !